5-AXIS MACHINING

EK 5-Axis Vertical CNC Machining

As part of our mission to offer our customers the most cutting-edge, adaptable, and efficient machining capabilities, EK has expanded to include brand new 5-Axis Vertical CNC Machining.

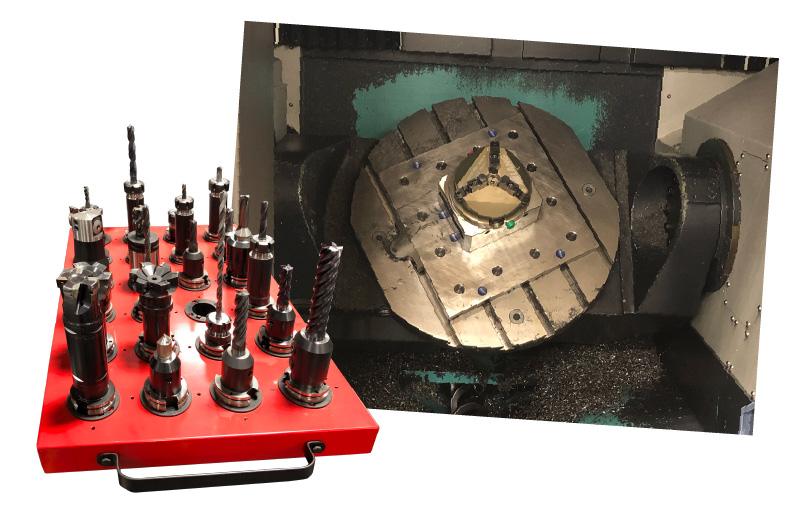

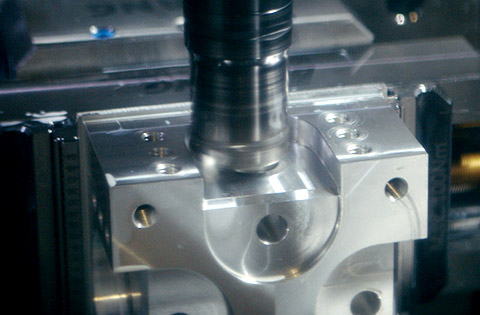

Our 5-Axis Machining capabilities are calibrated for a wide range of challenging and complex applications including curved and precision hole cutting. This level of calibration allows tools to move along the X, Y, and Z linear axis while rotating on the A and B axis allowing a part to be machined from virtually any angle in a single setup. With 5-Axis machining, cutting tools can access hard-to-reach places with ease.

Minimize Cost and Boost Production Speed for Complex Parts

Our 5-Axis Machining capabilities include high accuracy Renishaw part probes for precision part alignment, fixture setting, and part inspection. This allows simultaneous machining of highly complex workpieces without requiring repositioning which greatly reduces the setup, fixturing, and cycling time. Multi-axis CNC machining services increase productivity and minimize costs associated with custom machined parts. Our 5-Axis CNC machining services serve a variety of industries including automotive, oil and gas, food production, earthworks, and general engineering. And, we have qualified sources to finish, grind, heat treat, and plate to your requirements.

5-Axis Machining Capabilities

The Doosan VC630 5AX 5-Axis VMC can accommodate a part size up to 28.74” (730 mm) diameter and up to 19.685” (500 mm) height with a 1,100 lb (500 kg) table capacity. The X-axis travel is 25.6” (650 mm), the Y-axis travel is 30.1” (765 mm) and the Z-axis travel is 20.5” (520 mm) on a 24.8” (630 mm) universal table. The 5-Axis machine has an automatic tool changer with capabilities up to 80 tool holders.

5-Axis Machining Specifications:

- 5-Axis Machining Envelope of 28.74” diameter x 19.685” height x 1,110 lbs

- Movement along X, Y, and Z linear axis and rotation on A and B axis

- Machine highly complex custom parts

- Enhance accuracy and precision for finished products

- Reduce setup, fixturing, and cycling time

- Increase productivity and minimize costs

TURNING CENTERS

Adaptable, state-of-the-art CNC turning for effective subtractive manufacturing

MACHINING CENTERS

Efficient, automatic tool change overs for complex metal machining and die manufacturing