TURNING CENTERS

EK Turning Centers

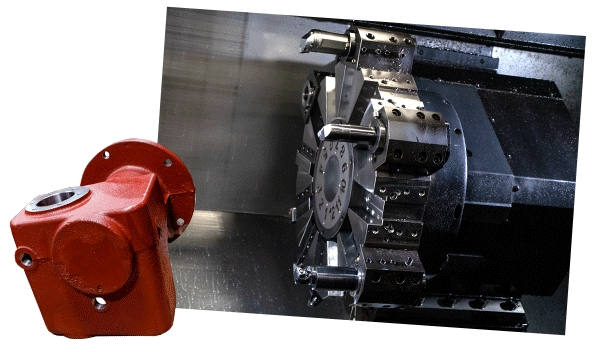

EK’s production facilities include a number of CNC turning centers with live tooling for precise machining of cross holes, flats, and keyways.

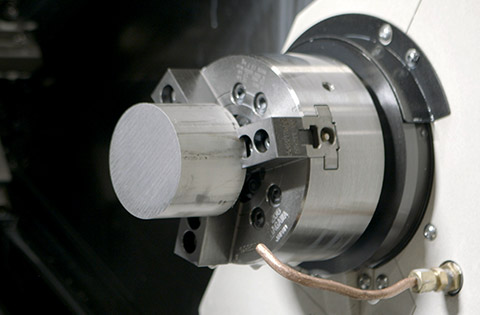

Our turning centers integrate milling, drilling, and sub-spindle capabilities along with a y-axis allowing our manufacturing team to drill, bore, and ream easily, cut a taper more precisely, create clean edges, and cut pieces to the correct length. These turning centers can accommodate stock from 5/16 to 22 in. diameters and 12 ft. lengths up to 2 in. diameter with our continuous bar feeders. Larger diameter components may have reduced machining lengths (consult the factory).

EK’s facilities also include close tolerance CNC saws and a horizontal broach to complement our bar stock production capabilities.

We also have qualified sources to finish, grind, heat treat, and plate to your requirements.

Turning Capabilities

Our turning centers offer a wide variety of capabilities. Our multi-axis turning centers allow multiple operations to be completed in a single machine. This allows tighter tolerances to be held and parts to be completed quicker because all operations are done at one time.

Available Sizes:

- Bar Stock from 5/16 in. to 22 in. diameter and 1/2 in. to 12 ft. lengths

- Larger diameter components have reduced machining lengths (consult the factory)

Explore Our Other Production Machining Capabilities

MACHINING CENTERS

Efficient, automatic tool change overs for complex metal machining and die manufacturing

5 AXIS MACHINING

Two rotational axes combine with three conventional axes to enable machining of even more complex shapes